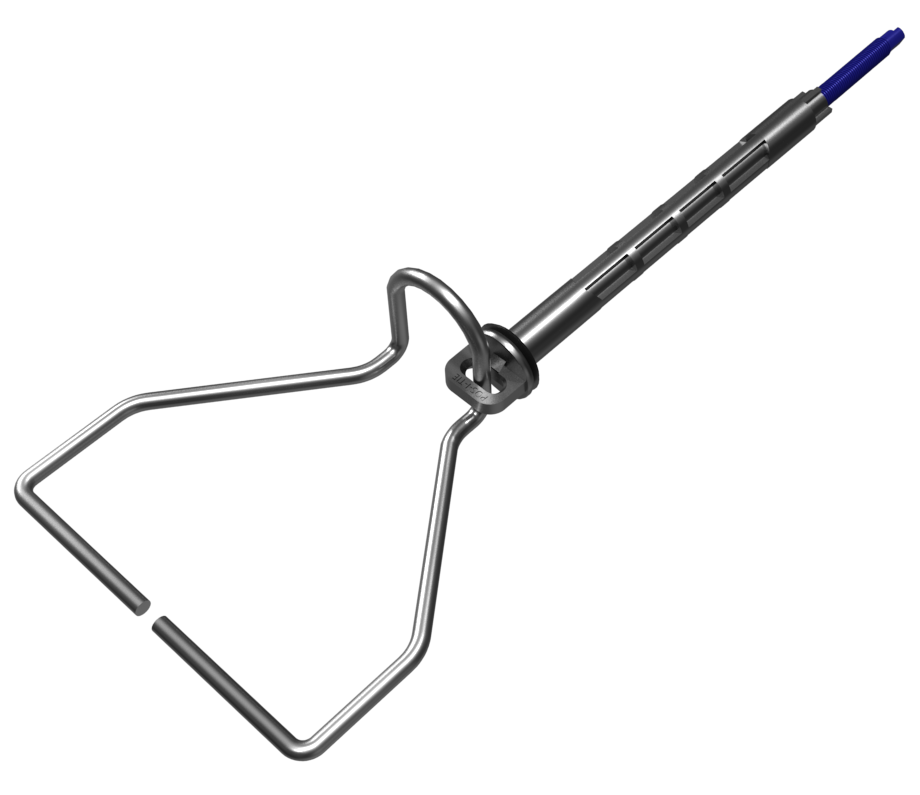

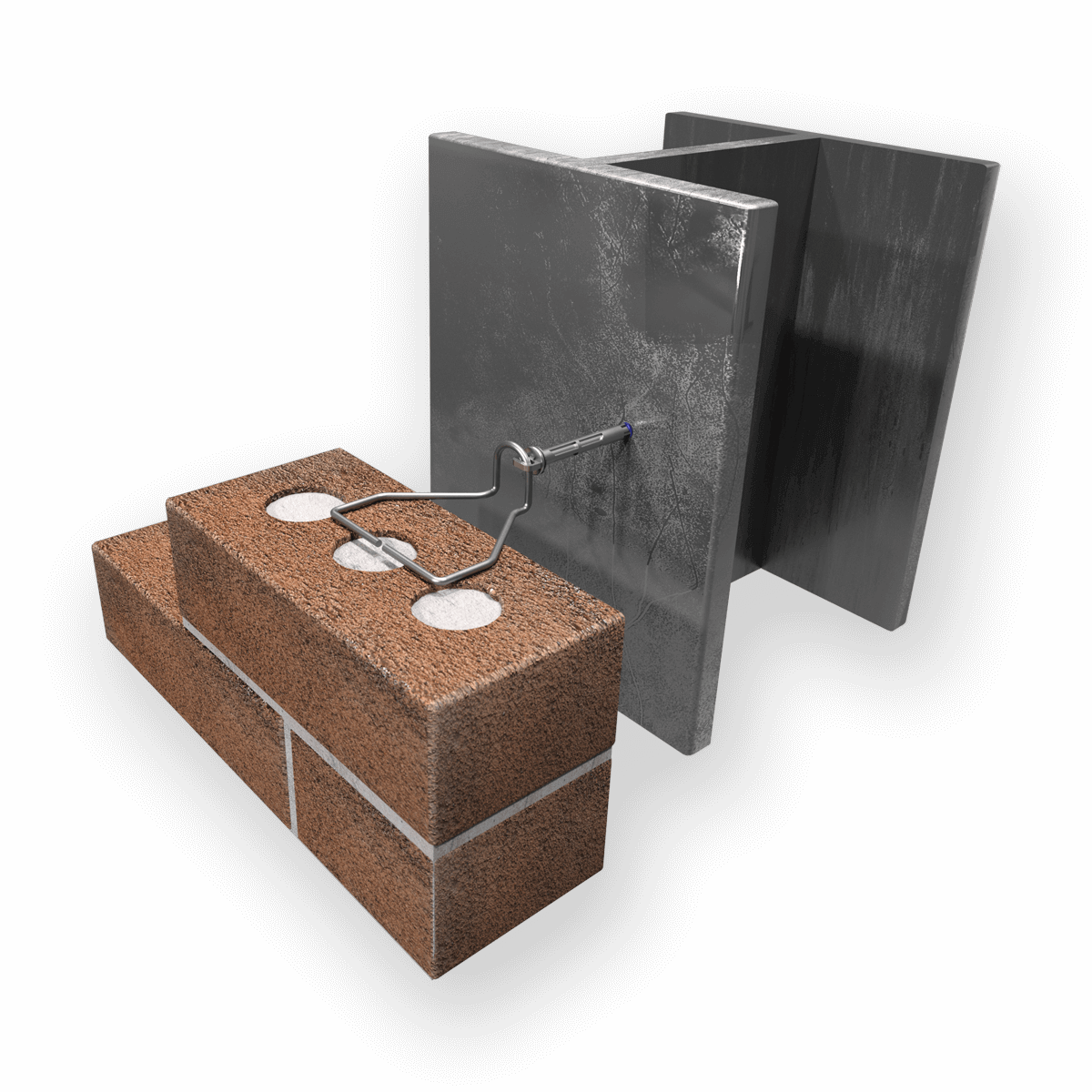

The Original Pos-I-Tie® Brick Veneer Anchoring System (75)

Part Number: 75

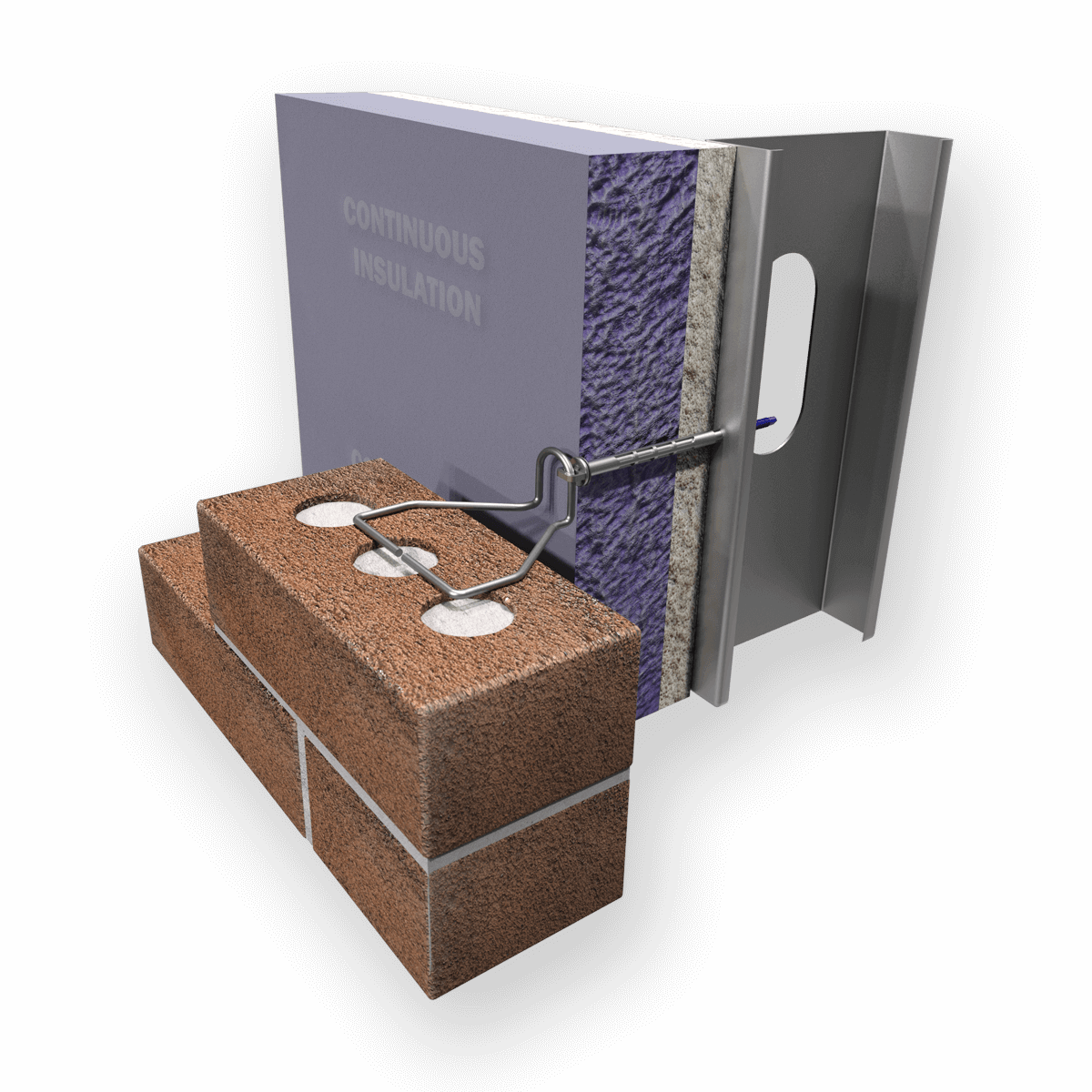

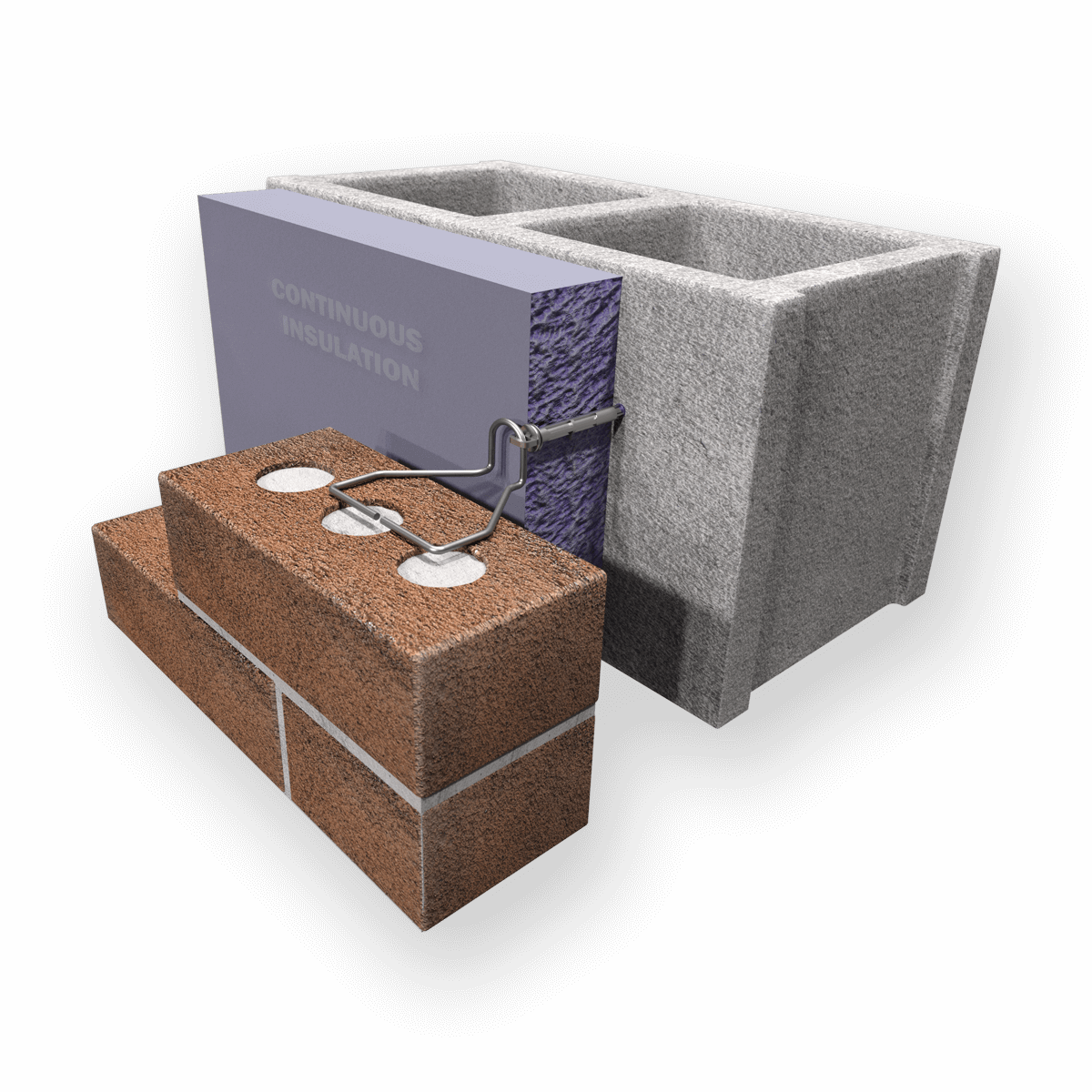

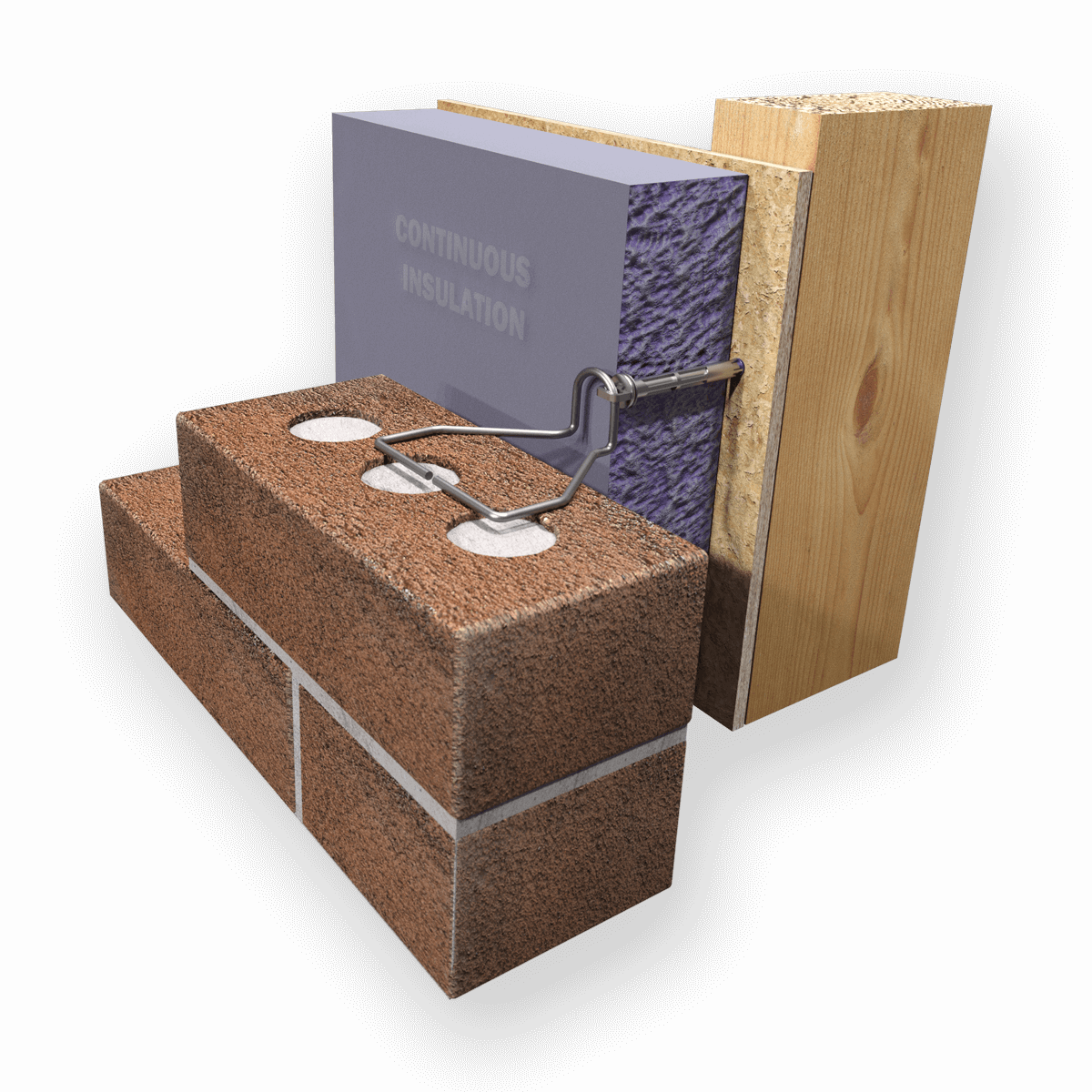

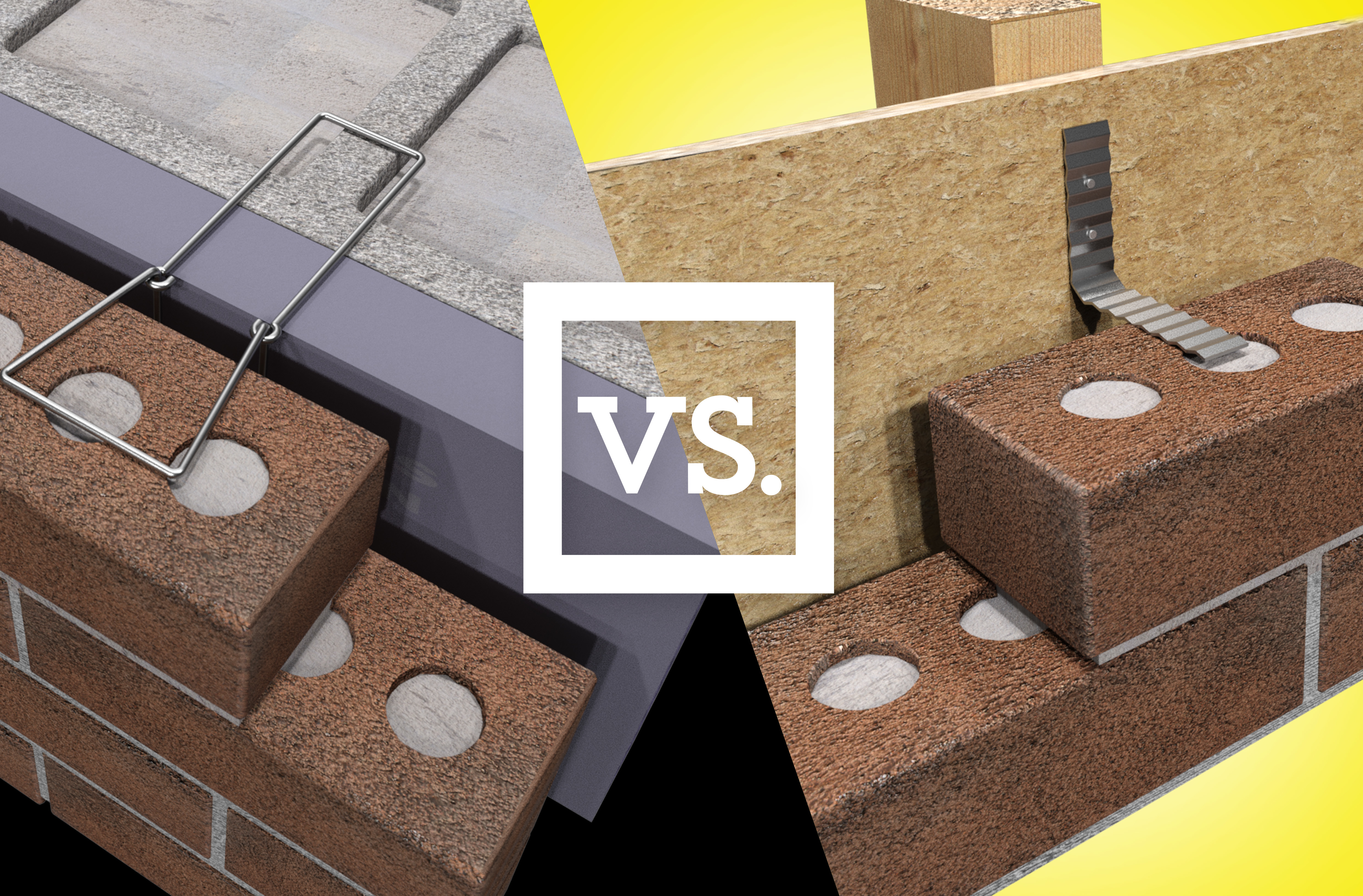

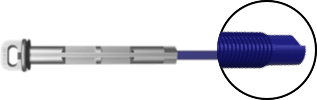

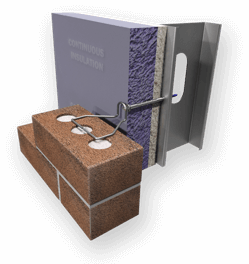

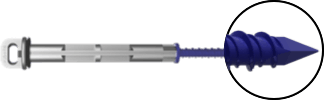

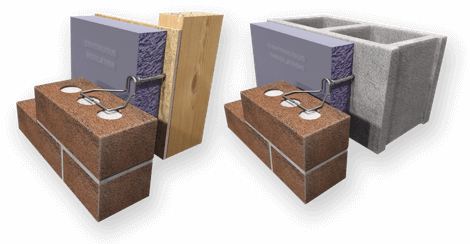

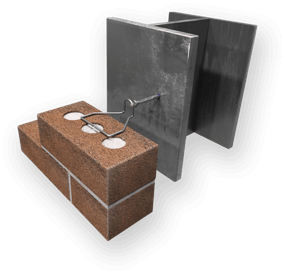

The Original Pos-I-Tie® is a two-piece system for attaching brick and stone veneer to various existing backups. It simultaneously penetrates the exterior insulation, makes positive contact with the backup for transfer of lateral loads, and seals the hole in the insulation with an EPDM washer under the barrel head. Introduced in 1985, The Pos-I-Tie® was the first barrel screw in the industry and has been successfully anchoring veneers for 35 years.

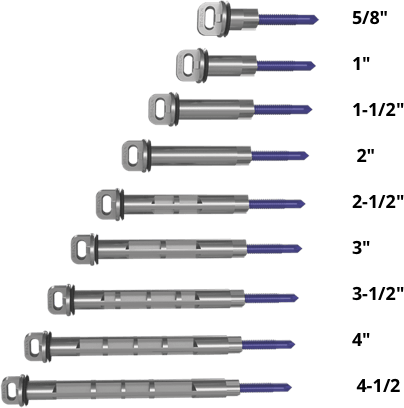

Standard sizes for sheathing thicknesses of 5/8", 1", 1-1/2", 2", 2-1/2", 3", 3-1/2", 4" and 4-1/2".

Custom lengths beyond 4-1/2" are available.

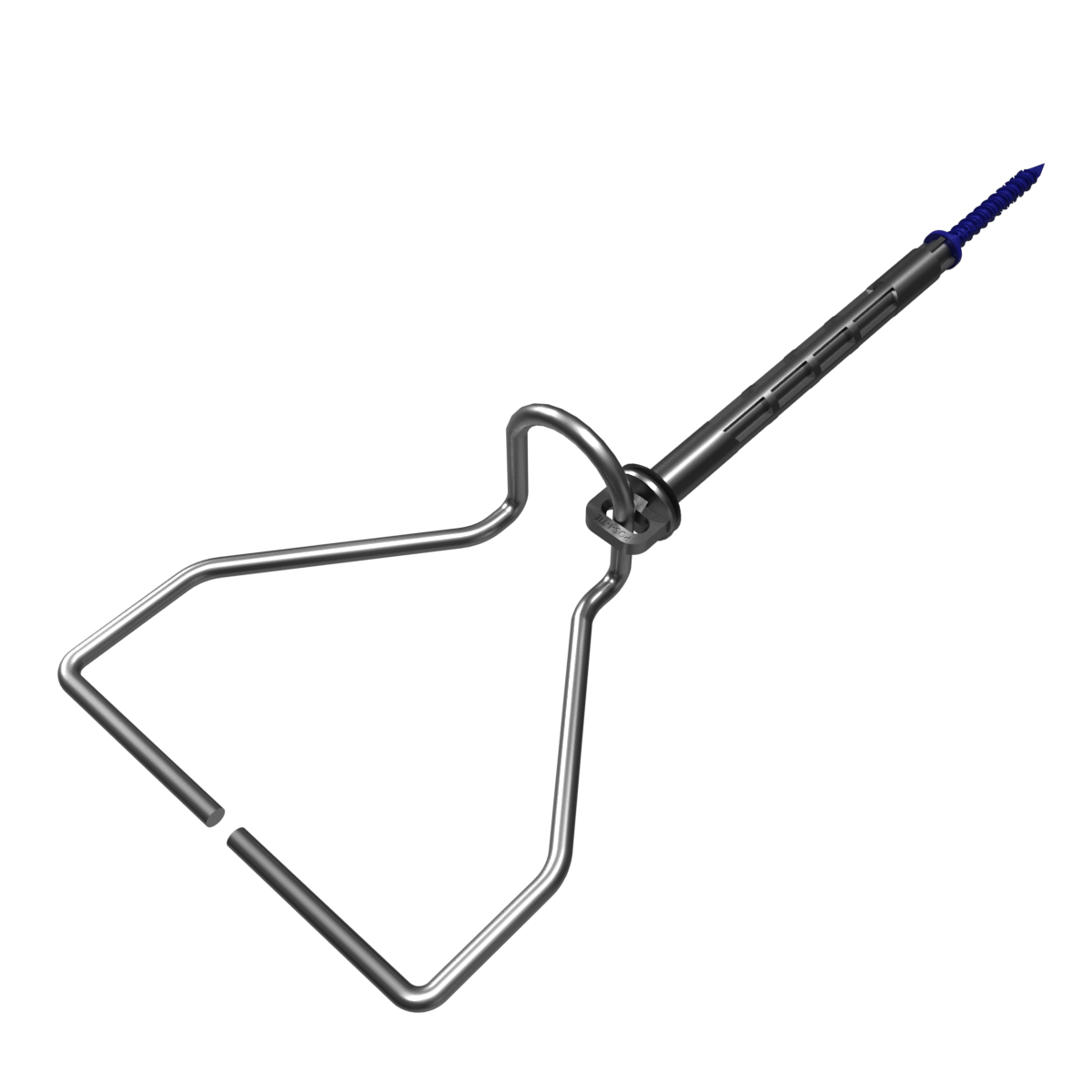

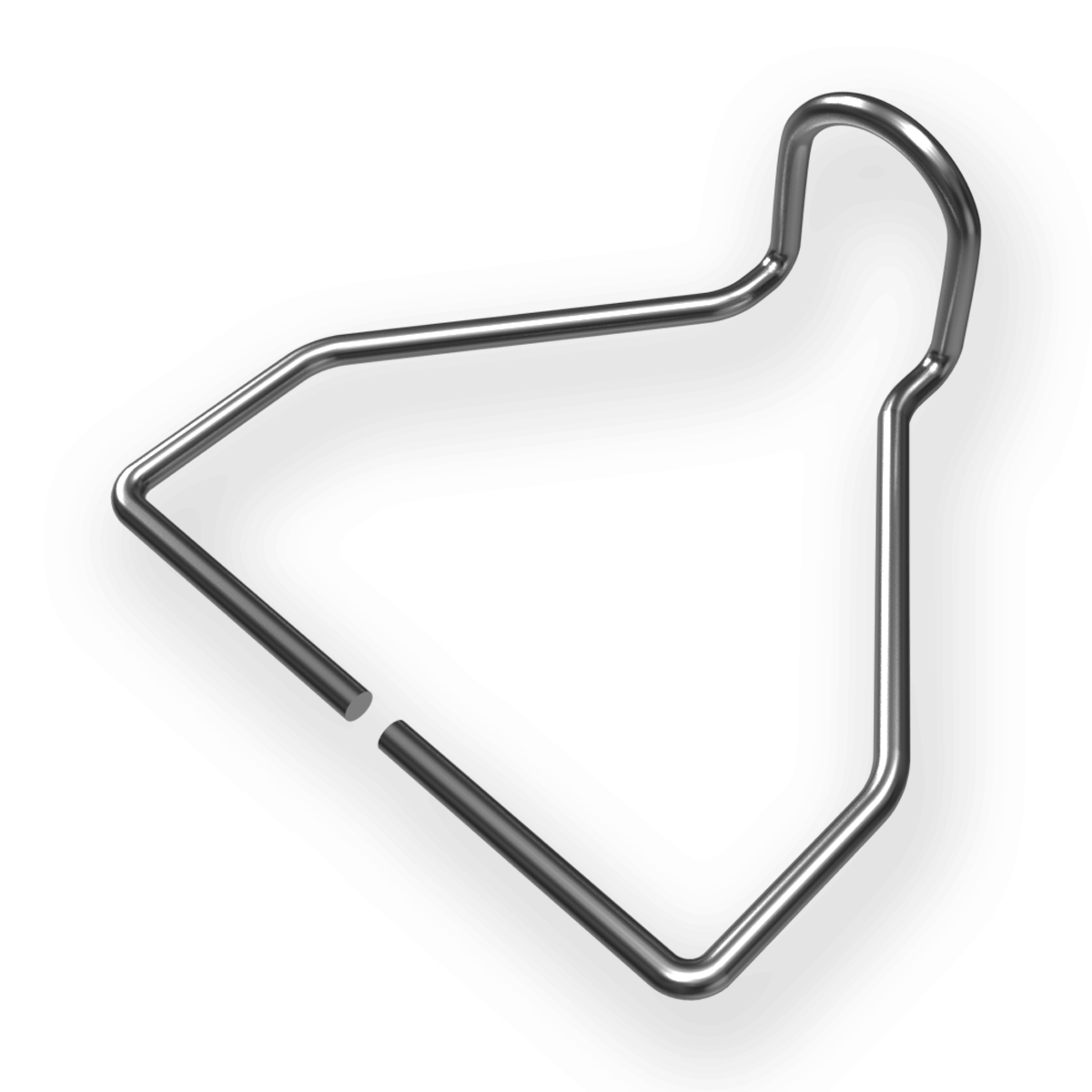

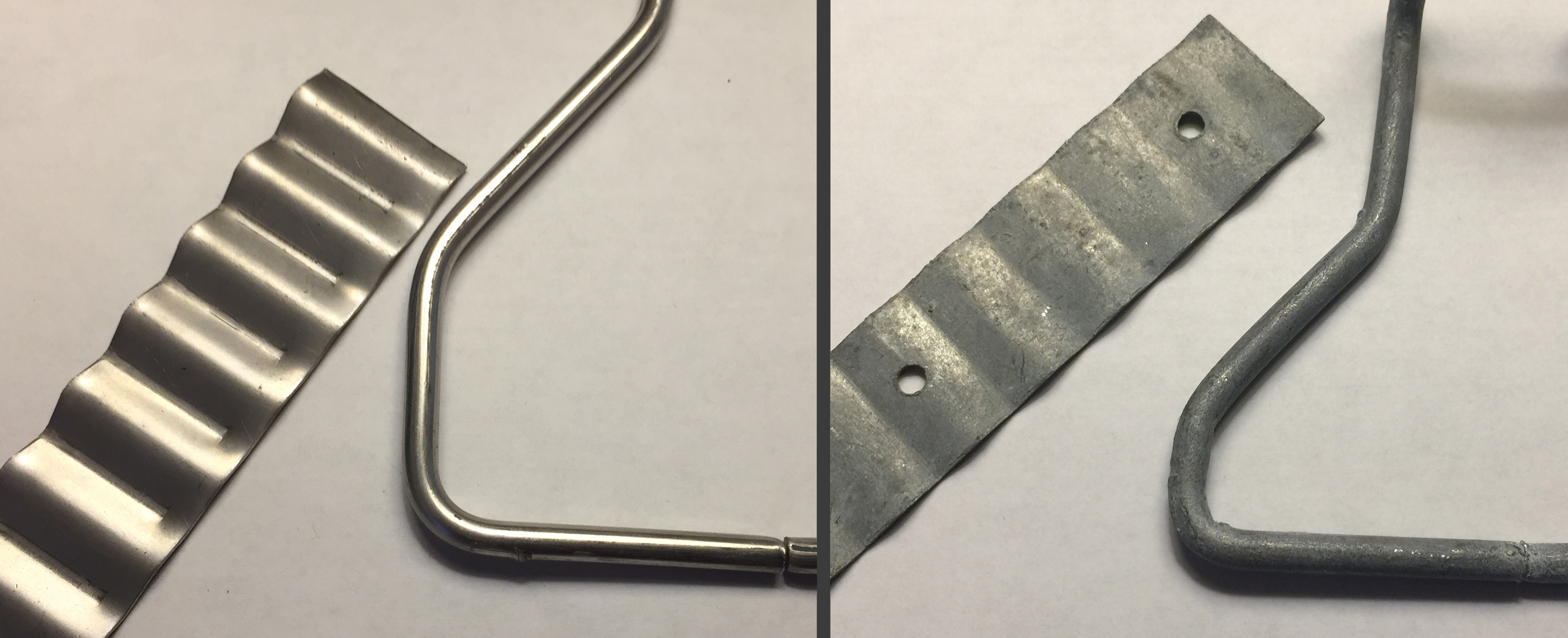

Pos-I-Tie® 3/16" diameter Wire Triangle Ties available standard in lengths of 3", 3-1/2", 4" and 5" in hot-dip galvanized and stainless steel. Custom wire tie lengths are available.

Resources

Features and Benefits

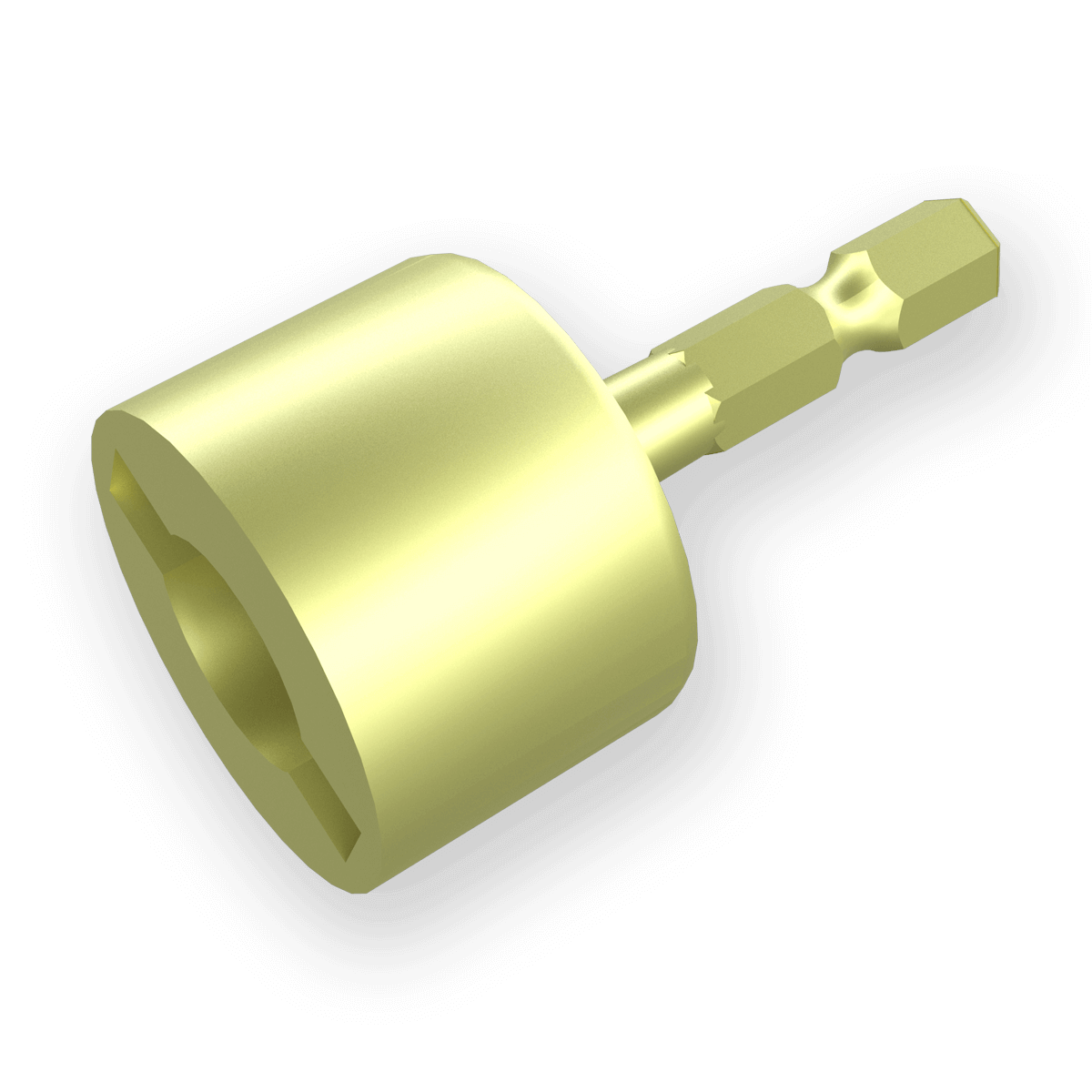

Incorporates a barrel-screw piece for easy installation using an ordinary drill with a special chuck adapter

Integrated screw prevents substitution and use of inferior screws

Doubles as an insulation fastener and a masonry anchor, reducing the number of penetrations in insulation

Installs safely with a rounded head and round chuck adapter, keeping fingers out of harm’s way from spinning wings

Does not require an additional washer between gypsum and rigid insulation

Materials/Finishes

The 3/8" diameter barrel is manufactured of ZAMAC 2 - a 92% zinc alloy

Screws are heat treated and co-polymer coated for maximum corrosion resistance

Wire ties are available in hot-dip galvanized after fabrication or stainless steel

Compatible with all back-up walls

Self-Drilling Screw

Used for: steel stud 18 ga – 14 ga

Concrete/CMU Screw

Used for: concrete, CMU, wood, brick, ICF

Structural Screw

Used for: structural steel

Barrel Lengths

Pos-I-Tie Original

The Original Pos-I-Tie® Brick Veneer Anchoring System (75)

Downloads

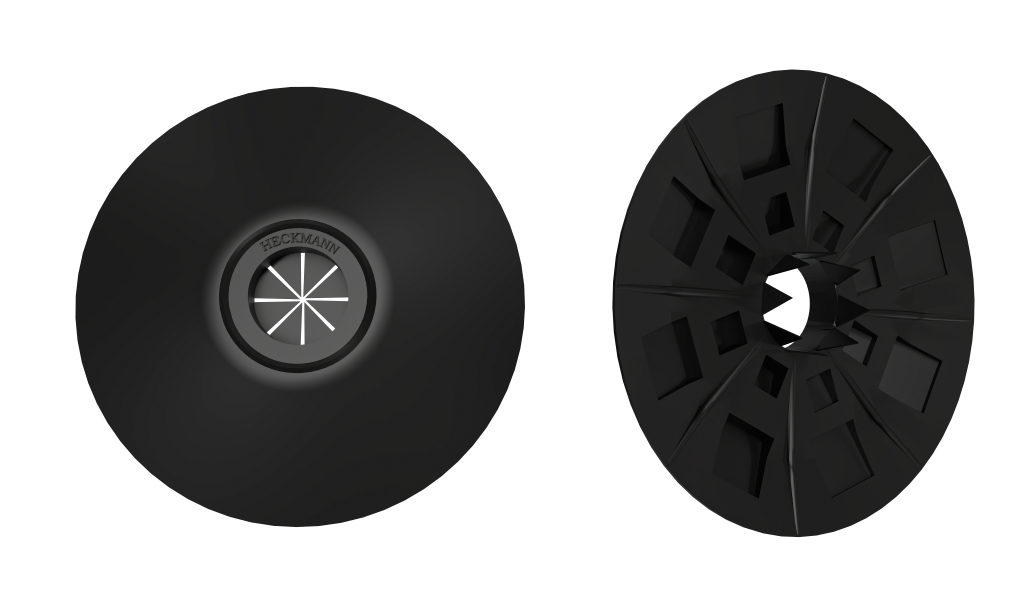

Pos-I-Tie® Installation Tools

Downloads

Pos-I-Tie® Triangle Wire Ties

Downloads

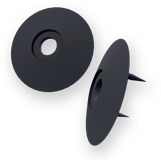

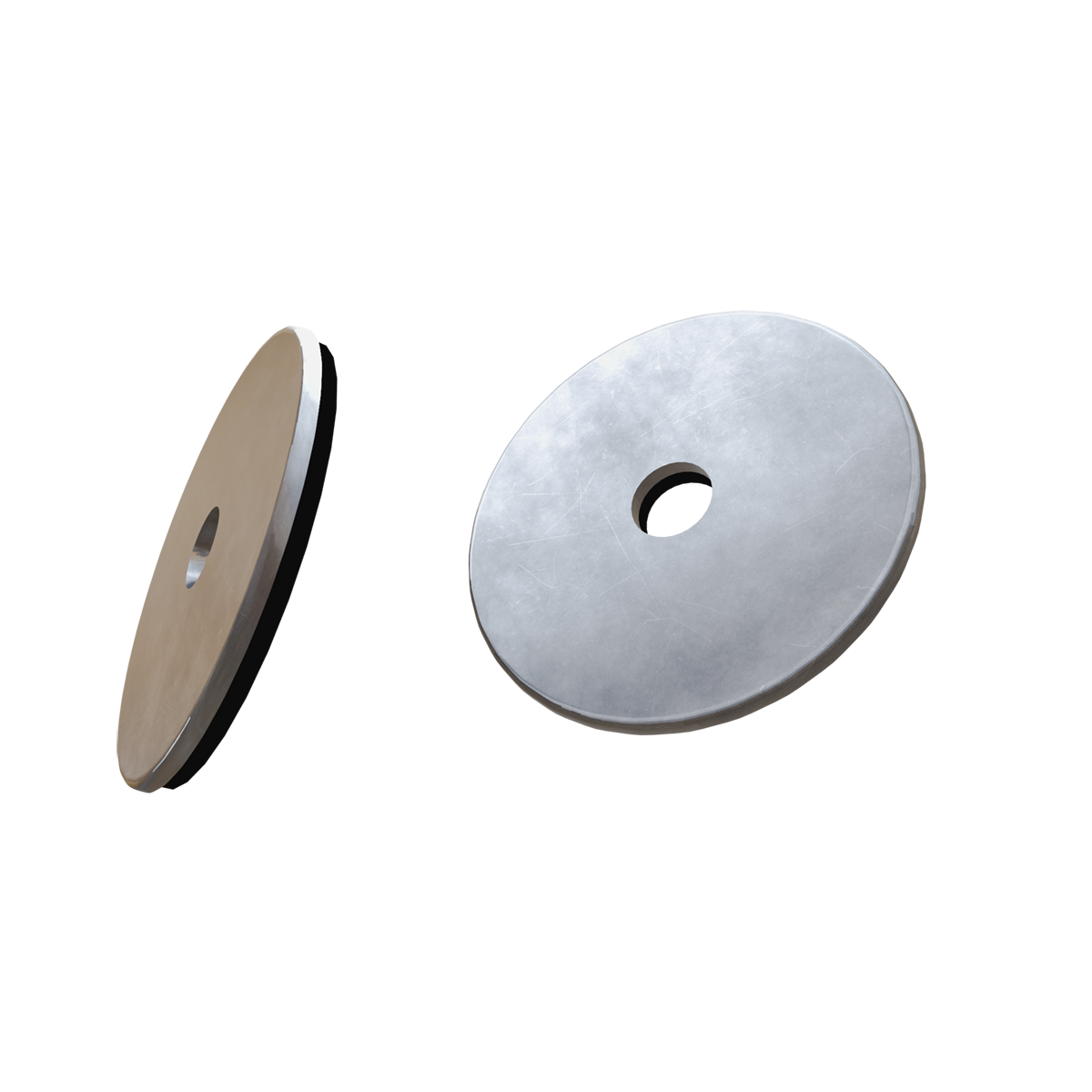

Pos-I-Tie Large Steel EPDM CI Washer (75-SW)

Downloads

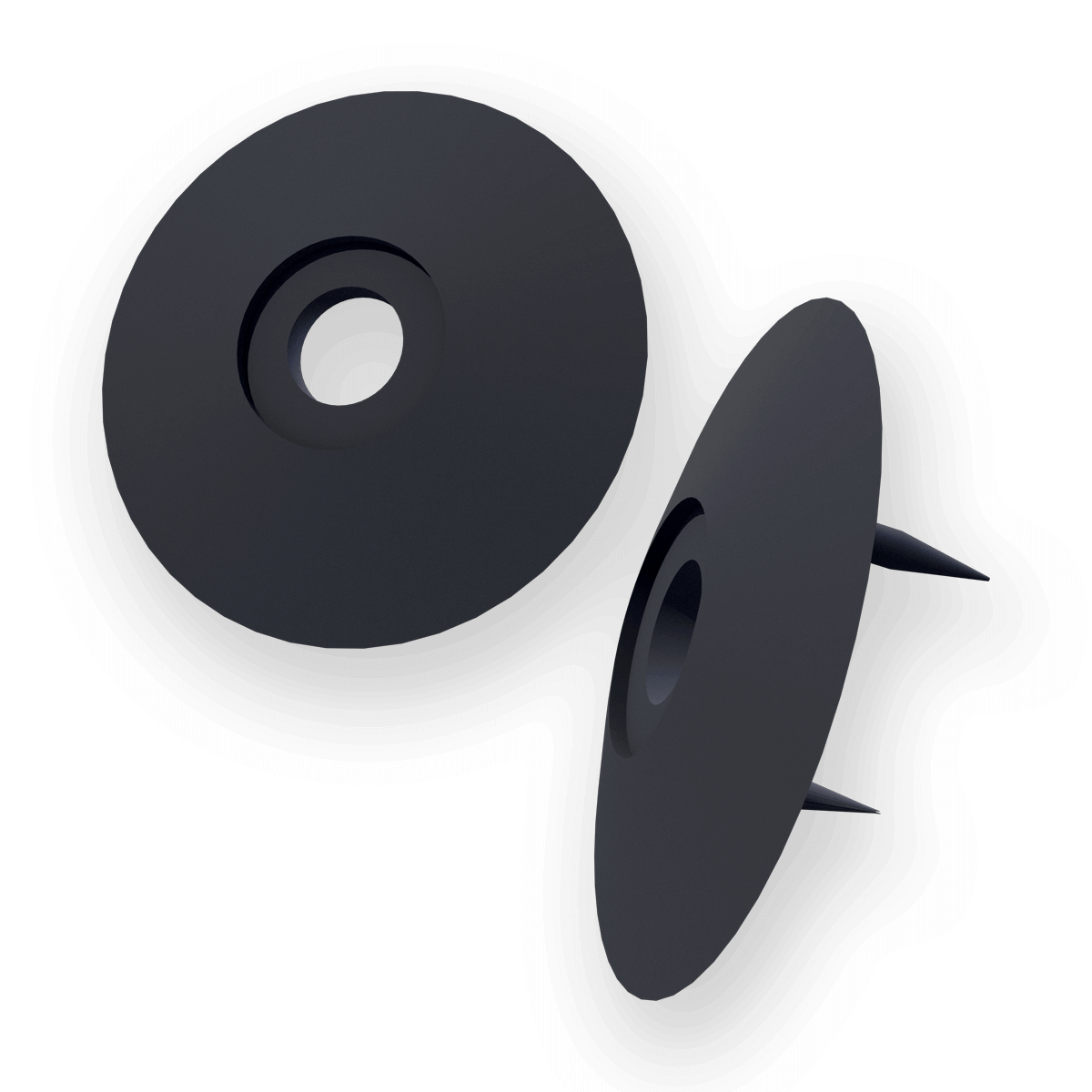

75-PW - Plastic CI Washers for Pos-I-Tie®

Downloads